Measuring Services

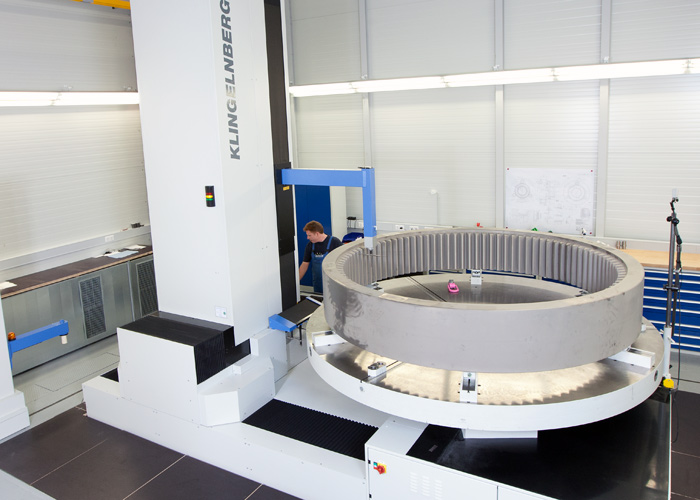

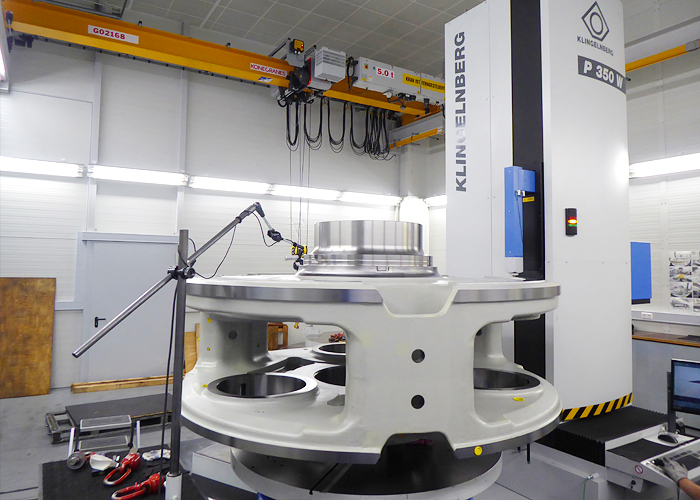

Air-conditioned measuring-environments

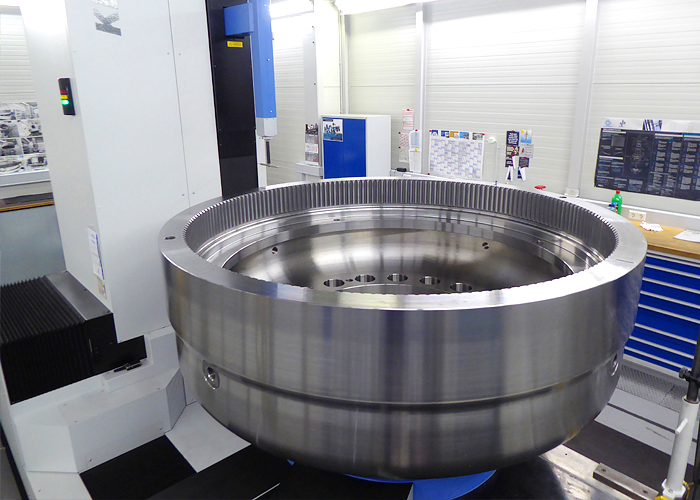

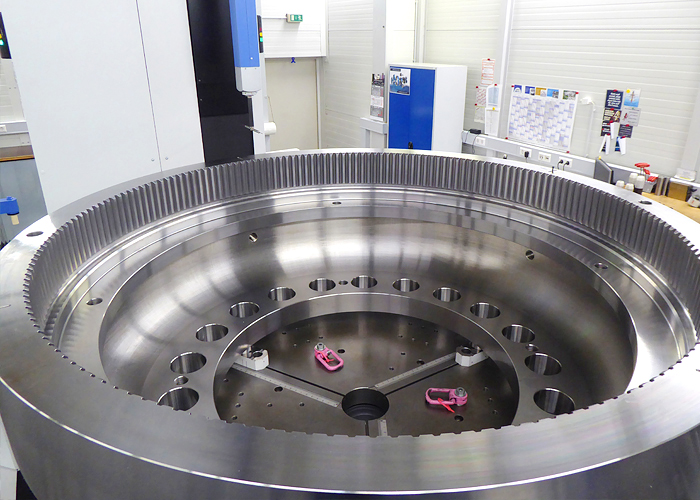

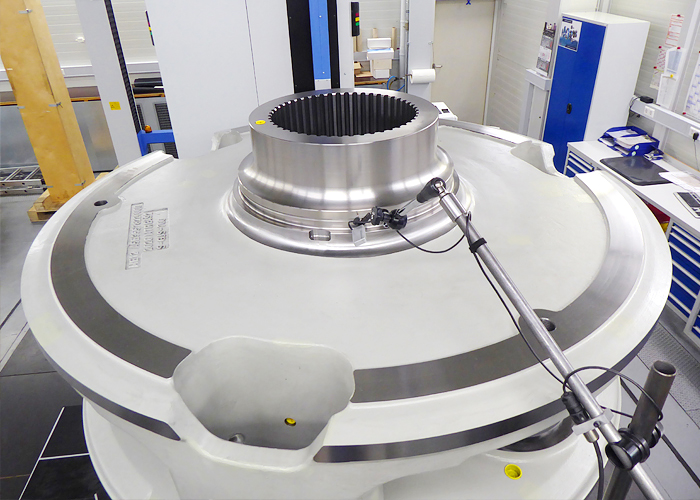

Constantly growing customer demands on our products require us to monitor our services by strict quality control. The quality of our portfolio (with our main products gears and worm drive parts) is being ensured by the following measures:

- Air-conditioned rooms for measuring machines with an integrated storage place for the acclimatization of workpieces.

- OTT Worm Gears, as well as all common worm drives, are subjected to a single flank rolling test.

- Upon customer’s request, gearings of worm gears and worm screws can be measured on our measuring machines.

- Machine operators are performing quality measurements in the running production process.

- Depending on specification of the product, we provide documentation of testing and measurement results.

- Measurement results can be visualized graphically.

Technical data for gear tooth measurement:

| Work piece diameter (Ø) | max 3,800 mm |

| Weight (t) | up to 20 t |

| Length | up to 2,000 mm |

Technical data for coordinate measurement:

| Measured displacement X / Y / Z | up to 3,000 x 4,500 x 1,600 mm |

| Weight (t) | up to 20 t |

Additional Services / Qualifications:

- DGZfP certified testing team

- Constant monitoring of measuring- and test-equipment

- Identification and traceability of our products

- Crack testing: magnetic particle inspection / penetration test

- Ultrasonic testing

- Grind burn testing is performed following the Barkhausenrauschen-Analysis (BNA)