History

The history of Zahnradfertigung OTT

2021

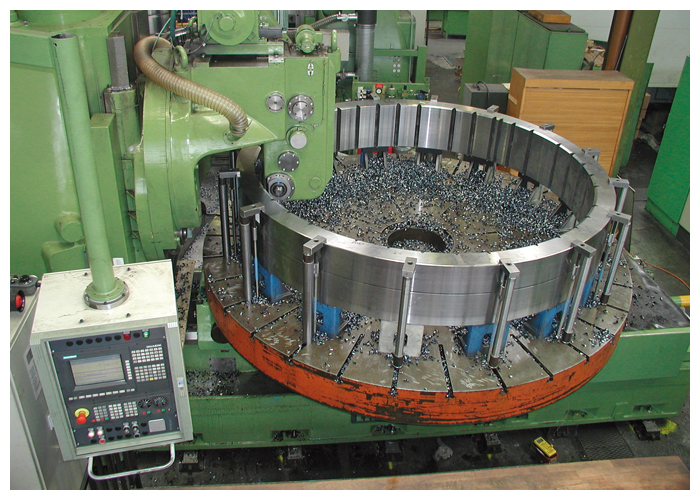

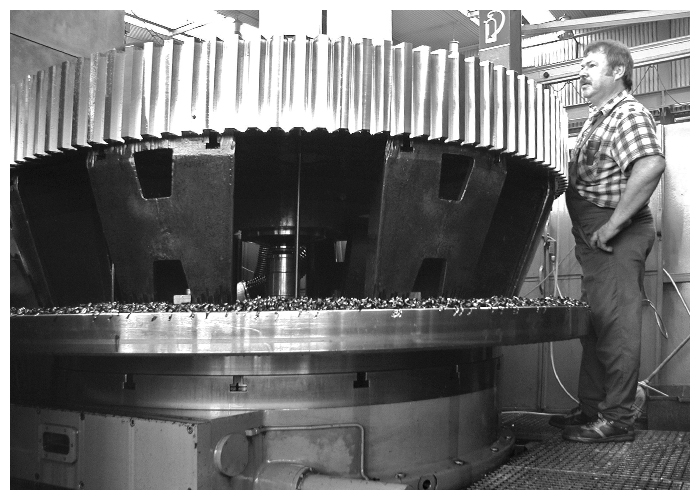

Purchase of a Gleason Pfauter P4000 hobbing machine to expand our range up to a diameter of 4000mm.

2020

To expand our portfolio, we are investing into an additional vertical lathe. By doing so, we will be able to offer complete manufacturing up to 3,500 mm in diameter.

2018

Doris Haag, Erwin Haag and Norbert Ott are handing over the company’s management to Jens Haag and Frank Ott.

2017

Our company is celebrating its 60th anniversary. The festivities involved a family day for our team and the big moving-in into the newly built Hall H. The hall opened up 1,000 sqm of new space for complete manufcaturing of our wind energy sector. Furthermore, it involves a newly built trainee workshop!

2015

On a production area of ca. 9,500 sqm Zahnradfertigung OTT manufactures gearing technology of the up most quality for the national and international market. To where ever gear parts are needed.

2014

With the investment of another large lathe, we have also invest in a big machining center. Thus, we are now finally grown to a manufacturer for complete gear components and can supply our customers with complete components for their gearboxes.

2011

In mid 2011 Zahnradfertigung OTT and Welter Lahr took over the Siemens manufacturing of CAVEX. Supply sources at www.cavex-gmbh.com

2009

In our production site constructed in 2008 our grinding machines, a large lathe and a coordinate measuring machine were installed.

With these investment Zahnradfertigung OTT was once again one of the first to offer a full assembly for large inweaving gear parts.

2008

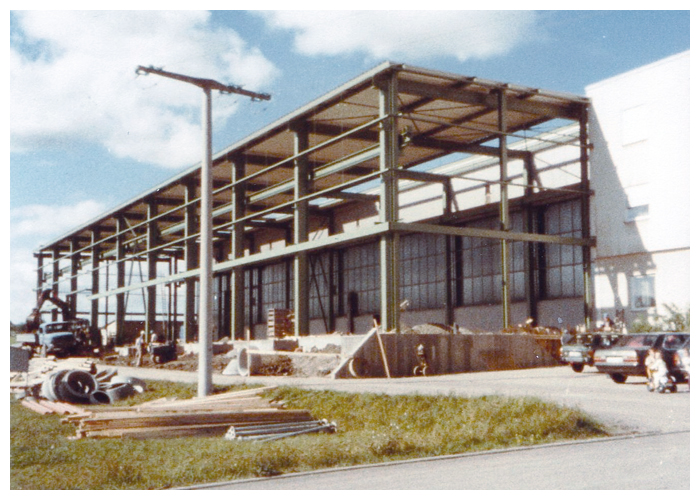

The trust of the wind energy customers in Zahnradfertigung OTT and the good prospects and commitments for the coming years lead us to the construction of a further production site of the size 2,000 sqm. The entire prepatory work for the ring gears destined for wind power applications was integrated there. The site was finished in 2008.

2000

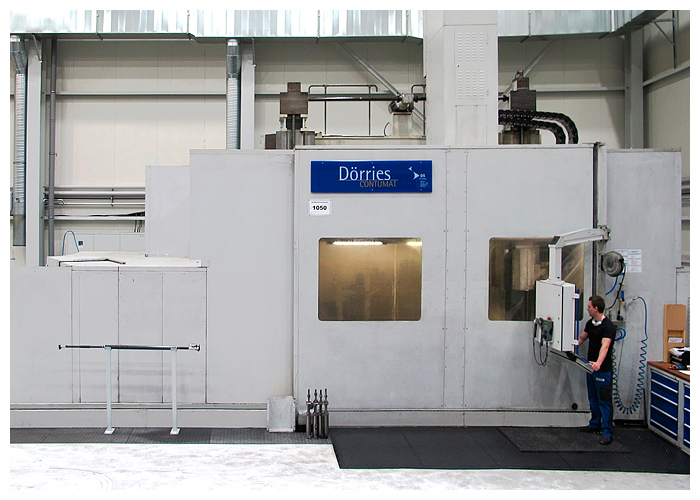

The high quality requirements of the gearboxes for wind power systems soon demanded sanded gears for the internal gears. To meet this new requirement the OTT company decided in late 1999 to acquire machinery for the sanding of internal gears with the maximal ranhe of 2,500 mm in diameter. Untill then, this had been the largsest investment for machinery.

1999

A machine internal gearing facility had to be altered for the processing of helical internal gears. With this machine Zahnradfertigung OTT was the first in Europe to have the technological expertise to manufacture helical internal gears with carbide tools. This machine was the basis for becoming a supplier of turbine gear boxes.

At this point Zahnradfertigung OTT had 120 employees.

1998

Meanwhile the gear manufacturing and general grinding business was also running under good capacity which lead the production scale had to be increased again. The entire gear production was integrated at the new site.

1995

Company founder Gerhard Ott passed away after a long illnes in 1995.

1988

The customer reqirement of highest precission for OTT Worm Gear was met. Specialized machinery was integrated. Highprecision testing devices for decumenting and measuring of the produced quality were procurred at the same time.

In this way, our worm gear poduction line devloped into the top-selling product by the end of the 1980’s. almost 60% of the total revenue was generated by the worm gear line.

1982

As history tends to repeat itsself soon the large production site did not offer enough space for any further investment. The first extension in the Blöhsteinstraße was put into action. The entire gear manufacturing was integrated into the newly established production site. Thus the basis an extension of the production of worm gear units was given.

1975

The number of employees grew continuously. By the mid 1970’s 60 workers were employed. Wage employment of the interweaving department flourished in the following years and orders for worm and wheel sets improved steadily. In the meantime, the staff of the technical bureau was strengthened. With these measures we were able to offer customers of worm gear units an adequate and competent consulting service in order to solve their drive tasks. This was an important step to further strengthen the development of the production process.

1971

Now the meanwhile 43 employees could move into the new production site in the Blöhsteinstraße. The courage of Gerhard Ott to take this large step of moving from the small and cramped conditions at Butzensee to new production site of 2,000 sqm went with high risk.

1970

The operation was overcrowded with 24 employees. As a consequence, a new property at the Blöhsteinstraße was acquired.

1969

The area at Butzensee became too small for further structural expansion.

1963

An additional extension was finished.

1961

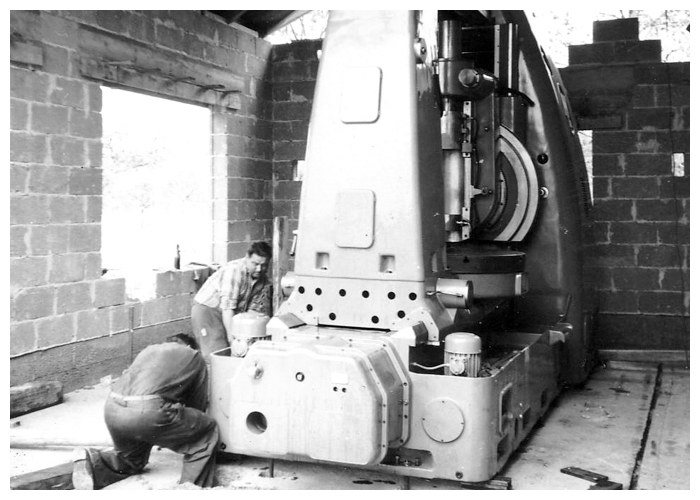

Structural expansions at the the old production site could not keep up with the procurement of machinery. The cramped situation even lead to the consequence that in 1961 a large gear hobbing machine had to be positioned within the still unfinished structures of an extension.

The extension was completed as quickly as possible thereafter.

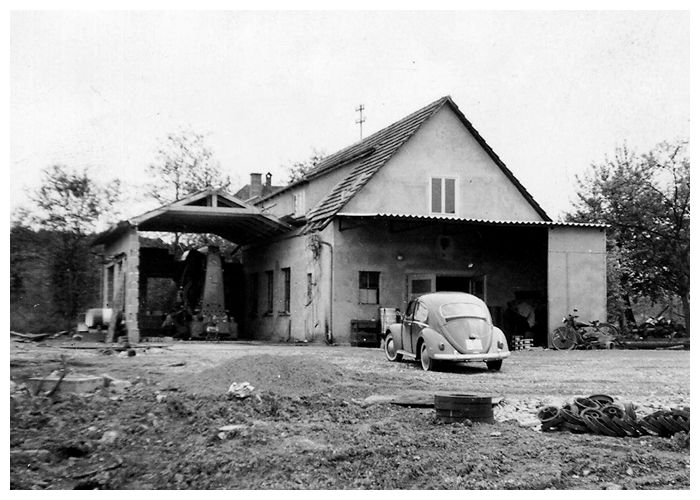

1957

Gerhard Ott has registered his own company under the name “Gerhard Ott Mechanische Fertigung” with the Reutlingen Chamber of Commerce.